-

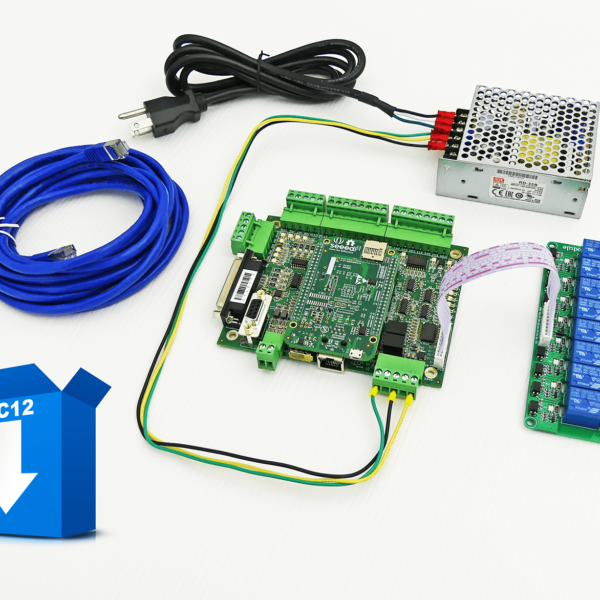

A CNC machine tool operator control panel interface board that connects to the CNCPC via a USB port. The Operator Control Panel Interface Board is intended to be an affordable, reliable, alternative to traditional methods of building CNC control operator control consoles/panels. The USB-BOB provides inputs for the most commonly used operator controls in a package that installs quickly with minimal fuss saving on wiring/installation labor and CNC controller inputs. It features inputs for three standard rotary encoders with integrated push-button, three MPG hand-wheel encoder inputs, 12 optically isolated switch inputs, and 12 open collector LED outputs. The USB-BOB can be used in conjunction with Centroid’s popular Virtual Control Panel or without.

- Centroid "USB-BOB" kit (#15380) includes:

- 1x Made in USA Centroid USB Operator Control Panel board

- 3x Feed Knob Assemblies with cables

- 3x 10-pin Terminal Blocks

- 4x 5-pin Terminal Blocks

- 1x 6' Right-Angled USB to Micro USB Cable

- 4x 6-32x1/2" Standoffs

- 4x 6-32x3/8" Screws

- 4x 6-32 Lock Washers

The Made in USA Centroid USB Operator Control Panel Interface Board (aka “USB-BOB”) is a Made in USA CNC machine tool operator control panel interface board that connects to the CNCPC via a USB port. The Operator Control Panel Interface Board is intended to be an affordable, reliable, alternative to traditional methods of building CNC control operator control consoles/panels. The USB-BOB provides inputs for the most commonly used operator controls in a package that installs quickly with minimal fuss saving on wiring/installation labor and CNC controller inputs. It features inputs for three standard rotary encoders with integrated push-button, three MPG hand-wheel encoder inputs, 12 optically isolated switch inputs, and 12 open collector LED outputs. The USB-BOB can be used in conjunction with Centroid’s popular Virtual Control Panel or without.

The USB-BOB is plug and play with preprogrammed button and knob functionality: Many common functions like Cycle Cancel, Tool Check, Feed Hold and Cycle Start along with Rapid Override, Spindle Speed Override and Feedrate Override are preprogrammed and user select-able with easy drag and drop installation.

In addition to these pre-programmed controls, all controls are user configurable through Centroid’s CNC PLC language so user can customize both the button or knob functionality to suit their application and tastes.

Common uses:

• Physical buttons and knobs for core/common operator functions simplifying the design for a hard operator console

• Supplement Centroid Virtual Control Panel with physical controls without using up any CNC control board inputs

• Add separate Rapid Override to Centroid Legacy control systems that did not have this feature.

Centroid "USB-BOB" Operator Control Panel Interface Manual

USB-BOB is compatible with CNC12 Mill, Lathe, Router, Plasma v5.20+ and is drag and drop super easy customizable using the Acorn, AcornSix, and Hickory Wizard.

When using the USB-BOB with the Centroid Allin1DC and Oak CNC control platforms there is no setup Wizard (like Acorn, AcornSix and Hickory), the USB-BOB is compatible with the Centroid Allin1DC and Oak CNC control platforms and is supported through a few CNC12 parameters (to let CNC12 know to look for a USB-BOB) and then the Centroid PLC program handles all the rest of the inputs and outputs for the USB-BOB. Note: For the Allin1DC and Oak it is required to edit the Allin1DC or Oak CNC controller PLC program to match your custom inputs and outputs of the USB-BOB and then compile it. The Centroid PLC source code is human readable, open source and the compiler and even a debugger is all available for free. Instructions on how to edit and compile Centroid PLC programs are published and we also offer the PLC program modification as a service (purchase here) if you don't want to do it yourself.

Compatible with:

Documentation & Support

This is a 110VAC Primary / 83VAC & 24VAC Secondary Step-Down Transformer

Capacitor and Rectifying Bridge not included, if you need the whole kit please see here.

This transformer is commonly used in Allin1DC CNC control system that use DC servo motors that are rated Below 155 VDC as their maximum input voltage.

Many common DC servo axis motors found on knee mills, bed mills made through out the 90's and 2000's are rated around 140 VDC as a maximum. So, these DC servo motors require this transformer is to "step down" 110/120 single phase VAC to 83 VAC which then is converted to DC power via Centroid's DC cap and bridge combo (#12726)

Note: These two Centroid products are sold together as well.

In the case of a new control system or if the retrofit step down transformer is missing or damaged Centroid sells this step down transformer kit for use with servo motors that are rated below 155 vdc as a maximum. DC Power Supply with Transformer Motor rated at 160 DC or greater do not need a step down transformer.

(Note: When using DC servo motors rated at 155 VDC and greater this transformer is not necessary. Centroid's current DC servo motors do not require this transformer as they are rated at 180 VDC max 110/120 VAC can directly be rectified with (#12726). Older Centroid servo motors did have a lower maximum voltage rating and would require a step down transformer.)

Acorn Plexi Cover Kit (#15343) Includes:

1x Plexiglass Cover for Acorn

4x 6-32x3/4" Standoffs

4x 6-32x3/8" Screws

If you are purchasing a new Acorn kit, you do not need to purchase this item.

Free Shipping for Contiguous USA, Add $12 USD for International shipping. Ships via First Class Mail (USPS).

Starting on July 3rd, 2023 these plexiglass covers are included with the purchase of an Acorn CNC Control Kit. This product listing is available for those who purchased an Acorn Kit prior to July 3rd, 2023 and wish to purchase a plexiglass cover for their Acorn Control Board or for those with a damaged cover seeking a replacement.

These are plexiglass covers, do not clean with Alcohol based products or damage may occur.

Compatible with:

This is the same hardware used on our Arm mounting kits and allows the installer to use an existing console support arm by adapting Centroid CNC console mounting hardware to that existing arm using this kit.

This hardware bolts to the existing arm and mounts to the Centroid M400/T400 CNC consoles allowing smooth swiveling action with adjustable resistance. Popular on retrofit applications or when the integrator wants to create their own console support system.

- All-in-one Touch Screen CNCPC (#15021,15022) Features:

- - Pre-loaded with Windows 10/11

- - Pre-configured for CNC PC duty

- - Pre-loaded with Centroid CNC software

- CNC12 'Free' Level of Selected Preinstalled Software Version

- G code Editor

- Intercon

- Stock PLC programs

- Touch Screen Operator Control panel

- Acorn Install Wizard

- - Touch Screen

- - Wifi, Ethernet, webcam with mic, card reader, USB ports

- - Powercord, Keyboard, Mouse

- - Centroid tested and pre-qualified to work with Centroid CNC controllers

- NOTES:

- Model, Specifications and COLOR may vary.

- There are NO VESA mounting holes on this unit.

The Centroid ALLIN1PC comes pre-configured for CNC Duty. It's ready to use and communicate with our Controls. The PCs run Windows 10/11 and are equipped with a Touchscreen. Product may vary from image.

- Centroid Mini CNCPC kit (#15023) includes:

- 1x Intel based Mini PC

- 1x Centroid Aluminum CNCPC Multi-mount Plate

- 2x M3x6 screws to mount the Mini PC to the included plate

- 1x 100-240 VAC power brick

- 1x Pre-installed and pre-configured SSD

- w/ Windows 11 (64-bit)

- w/ CNC12

- Centroid Mini CNCPC (#15023) Features:

- - Use a LCD monitor (not included), 1920x1080 recommended, Touch Screen supported but not required

- Preloaded with a licensed copy of Windows 11. Windows is pre-configured for CNC PC duty!

- Preloaded Centroid CNC12 software Mill, Router, Lathe, and Plasma 'Free' version

- Preconfigured with Centroid Software

- Preconfigured Notepad ++ G code Editor

- Mill, Lathe, Plasma Intercon Conversational compatible

- Centroid CNC setup Wizard (Acorn, AcornSix, Hickory)

- Touch Screen Operator Control compatible

- Intel processor and SSD (solid state drive)

- HDMI, Ethernet Ports, USB

- Includes Power cord. (Monitor, Keyboard, and Mouse are not included)

- Centroid tested and pre-qualified to work with Centroid CNC controllers

- NOTES:

- Model, Specifications and COLOR may vary.

Compatible with:

Documentation & Support

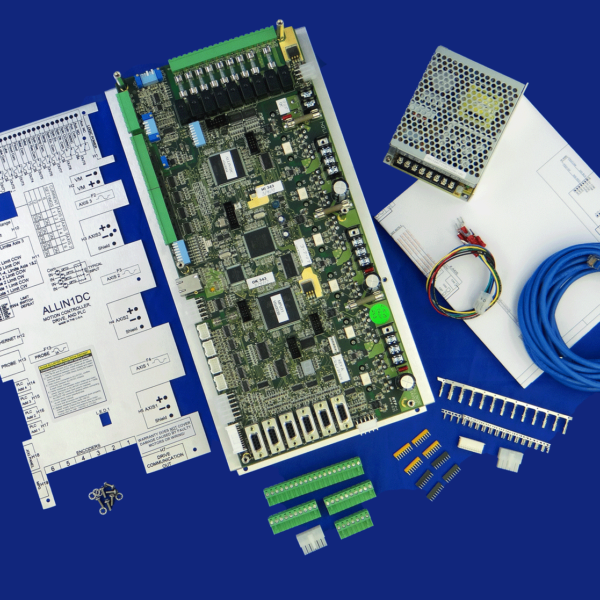

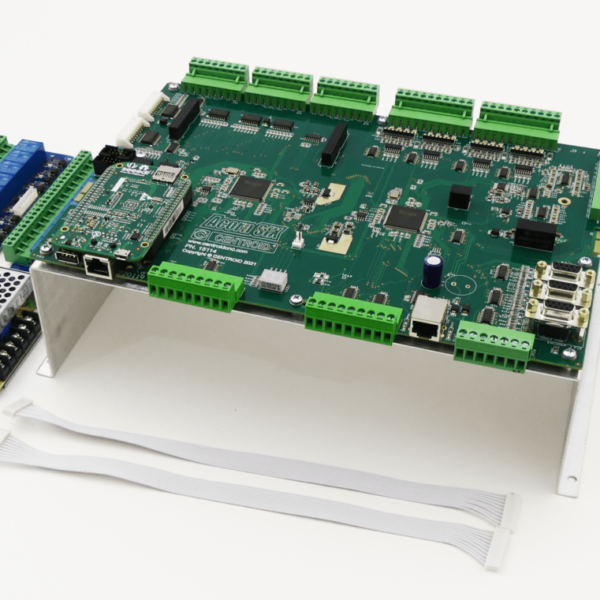

- Centroid AC/DC Servo Drive (#12854,#12855) includes:

- 1x AC/DC Servo Drive

The CENTROID AC/DC drive can power AC brushless servo motors (or large DC motors, hence the name AC/DC drive) with ratings of up to 4kW or 30 amps continuous output. Up to 8 axis can be controlled simultaneously. Popular on production machines where very high rapid rates are desired and on large machines which require high torque axis motors. The AC/DC drive can be used to run existing AC brushless servo motor when upgrading an existing CNC control saving money and installation time. Some motors will require an encoder upgrade. Please Email diysales@centroidcnc.com or Call 814-353-9256 to confirm compatibility with your servo motors before purchasing.

Documentation & Support

Centroid Allin1DC CNC Operator's Console with Integrated CNCPC (#13181) Features:

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Allin1DC, OAK and MPU11 systems. (not compatible with Acorn)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

Note: Optional MPG Shown in photo with Console

Note: Panel Mount does not include keyboard tray so it is not compatible with Mouse Tray and Utility Tray

Standard Mount is compatible with the Optional Floor Stand, Optional Mouse Tray, and Optional Utility Tray

Other mounting options are available, such as the Adapt to Existing Arm Kits (Direct Mount and Swivel Mount) and Arm Kit

Available with built-in CNCPC or without CNCPC, call or email for options.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console. )

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Depending on our current order volume, it may take us 2 days of processing before we are able to ship your order.

Documentation & Support

If you are looking to replace an existing stylus: The KP-1 comes standard with the 5 mm x 30mm Stylus (#2904). The KP-3 comes standard with the 2.5 mm x 40mm Carbide Stem, Ruby Tipped Stylus (#3357). The DP-7 comes standard with the 0.25" x 40mm Carbide Stem, Ruby Tipped Stylus (#3510) and a 100mm ceramic stylus extension (#8190). The DP-4 comes standard with both the 5mm x 40mm Carbide Stem, Ruby Tipped Stylus (#3360) and the 2.5mm x 40mm Carbide Stem, Ruby Tipped Stylus (#3357).

The KP-1, KP-3, DP-4 and the DP-7 use the same styli thread mount, so any listed styli will fit all four probes.

Centroid DC Servo Motor with Encoder and Cable (#12872, 10667, 10816, 10935, 12731) Features:

- Made in USA

- Windings specifically designed for torque characteristics needed for machine tool use

- Advanced ferrite long life brushes

- 180 VDC max voltage allows direct rectification of 110 vac so no transformer is needed

- 29 and 40 in-lb sizes are Nema 42 for compatibility as replacement motors on a variety of machine tools

- Centroid installed encoder and cable

- Centroid Tested and ready to run

- Backward compatible with older Centroid CNC control systems

- Available sizes: 10 in-lb, 16 in-lb 29 in-lb, 40 in-lb and 40 in-lb with brake

- Used on a wide variety of machine tools from knee mills, bed mills, lathes, VMC's, Routers and other specialty CNC machinery

Centroid CNC Operator's Console with Integrated CNCPC (#15098) Features:

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Hickory. (Not compatible with Allin1DC, OAK, Acorn, AcornSix, or MPU11)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

Optional Console Cable in Conduit (#15137) available with the console and also sold separately.

Note: Optional MPG Shown in photo with Console

Note: Panel Mount does not include keyboard tray so it is not compatible with Mouse Tray and Utility Tray

Standard Mount is compatible with the Optional Floor Stand, Optional Mouse Tray, and Optional Utility Tray

Other mounting options are available, such as the Adapt to Existing Arm Kits (Direct Mount and Swivel Mount) and Arm Kit

Available with built-in CNCPC or without CNCPC, call or email for options.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console.)

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Depending on our current order volume, it may take us 2 days of processing before we are able to ship your order.

Documentation & Support

Centroid Oak CNC Operator's Console with Integrated CNCPC (#13181) Features:

- 15" Touch Screen full color LCD display

- Dedicated Operator Control Panel with extra programmable buttons

- USB ports

- Thin at 2.88" Thick

- Made in USA Steel construction

- Uses Standard USB keyboards, keyboard included

- Variety of mounting possibilities

- Compatible with Allin1DC, OAK and MPU11 systems. (not compatible with Acorn)

- Optional Custom Control Panel Overlays are made to order for specialty machine tools. call or email for details.

- Preloaded Centroid CNC software (Free Version) with G code Editor, Intercon, Stock PLC programs, Touch Screen Operators Control Panel (VCP)

Note: Optional MPG Shown in photo with Console

Note: Panel Mount does not include keyboard tray so it is not compatible with Mouse Tray and Utility Tray

Standard Mount is compatible with the Optional Floor Stand, Optional Mouse Tray, and Optional Utility Tray

Other mounting options are available, such as the Adapt to Existing Arm Kits (Direct Mount and Swivel Mount) and Arm Kit

Available with built-in CNCPC or without CNCPC, call or email for options.

Available in "panel mount" configuration for mounting in existing console enclosure. (Panel Mount = made to bolt into an existing machine tool console space. Typically used on large machines with a preexisting CNC control so existing console hardware can be re purposed with new Centroid CNC operators console. )

Build your own console to machine mounting hardware or use any of Centroid various Arm and Console Floor Stand mounting options, click here for dimensional drawings

Download Centroid CNC console brochure click here..

Depending on our current order volume, it may take us 2 days of processing before we are able to ship your order.

Documentation & Support

Centroid Operator's Control Pendant (#11077):

Centroid CNC software allows operator machine control through a number of different methods.

This Operator's Control Pendant is for when hard buttons are preferred over touch screen controls. Useful on large and small machine tools alike when setting up parts, fixtures and tools, the pendant allows the operator to take the controls to where the work is. Steel case with magnets on the back and rubber handles, this control pendant uses the same operator control panel found in the M400/T400 CNC console.

The control panel can be removed from the pendant and flush mounted in your own console enclosure as well.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The touch screen VCP is included with Centroid CNC control software CNC12 v4.12+ and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Longer cords up to 50' are available call for quote or just use the Wireless MPG for long distance applications.

Same control panel that is on the M400/T400 CNC consoles but placed in a box with a 20' cord.

Compatible with:

Centroid Operator's Control Pendant for Hickory CNC Controllers (#15298):

Centroid CNC software allows operator machine control through a number of different methods.

This Operator's Control Pendant is for when hard buttons are preferred over touch screen controls. Useful on large and small machine tools alike when setting up parts, fixtures and tools, the pendant allows the operator to take the controls to where the work is. Steel case with magnets on the back and rubber handles, this control pendant uses the same operator control panel found in the M400/T400 CNC console but terminated for use with our Hickory ECat ethernet control protocol.

The control panel can be removed from the pendant and flush mounted in your own console enclosure as well.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The Touch Screen VCP is included with Centroid CNC control software CNC12 v4.12+ and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Longer cords up to 50' are available call for quote or just use the Wireless MPG for long distance applications.

Same control panel that is on the M400/T400 CNC consoles but placed in a box with a 20' cord.

Click here to view Hickory Example Schematic with Hickory Pendant

Compatible with:

This item has replaced by the NEW Centroid TRex Height Controller.

- Centroid THC controller kit (part # 15149, 15321, 15322) includes:

- 1x THC TX control board

- 1x THC RX control board

- 1x 5' Fiber Optic Cable (TX to RX connection)

- 1x 12" Shielded Serial Cable M/F Straight (RX-to-DB9 connection)

- Note: 18" and 36" can be purchased here

- 1x Din Rail Mount 24 volt power supply

Centroid's Torch Height Controller closes the loop between Plasma Arc Voltage and Torch Height via high-speed fiber optic communication.

The Centroid THC kit provides real-time closed loop operation between the arc voltage and the torch height. The THC reads the arc voltage and sends that information to the CNC controller via fiber optic isolation to Control Board's high-speed encoder port.

Part #15322 for PrimeWeld Cut60 and #15321 for Everlast i/s series include the special Centroid "CNC" cable from the Cutter to the Centroid THC Kit

Requirements:

- Acorn CNC controller kit

- An Acorn CNC12 Plasma Pro software license

- CNC12 v5.20+ Software

OR

- AcornSix CNC controller kit

- An AcornSix CNC12 Plasma Pro software license

- CNC12 v5.20+ Software

OR

- Hickory CNC controller kit

- A Hickory CNC12 Plasma Pro software license

- CNC12 v5.20+ Software

Documentation & Support

Acorn "Start Here" Web Page with requirements and How-to Videos.

Acorn CNC controller Hookup Schematics (type in "Plasma" in the search bar on this page to see all Acorn Plasma hookup schematics)

Acorn CNC Plasma Installation and Operation Manual

Acorn Hardware and Software Installation manual

All Acorn Documentation(a list of All Acorn related documentation)

Plasma CNC12 software download. (Note: CNC12 installation instructions are in the Acorn Installation Manual)

Plasma Intercon Download

Centroid Solid (.stp) Models

Centroid CNC Community Plasma Tech Support Forum (Free Tech Support!)

Acorn CNC controller buyers FAQ

- Centroid Servo Motor Cable "Direct Wire" Seal and Strain Relief Cap Kit (#5031) includes:

- 1x Aluminum Cap

- 1x Gasket

- 4x 6-32 Screws

For use with Centroid motor cables, this direct wire cable strain relief makes a water/oil tight seal against both the motor power and encoder cables to any flat surface. Very useful when converting both old and new servo motors to a direct wire configuration as seen on this page.

Centroid "Cap and Bridge Combo" Kit - 110VAC (#12726) Features:

- Easily powers up to four 29 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Preassembled, ready to use

- Commonly used for both new CNC control installations and retrofit upgrades

Power Conversion Examples:

- AC volts IN x 1.41 = DC volts out

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

See this DC Servo motor power discussion for more information.

Schematic is available in the ALLIN1DC Individual Circuit Schematic Set, see Page 5

Directly rectify AC voltage an generate DC power for use with the Allin1DC main DC servo motor power input.

For example, direct rectification of 110/120 VAC input will produce 155 DC volts for use with Servo motors with max voltage rating higher than 160 VDC, (no step-down transformer needed in this case for use with motors rated above 160 VDC max).

For motors rated under 155 DC volts as their maximum, use a step-down transformer in conjunction with this item. see typical hook up schematics below.

For most retrofit applications where the machine was already equipped with DC servo motors this step down transformer will already exist in the electrical cabinet and can often be reused.

In the case of a new control system or if the retrofit step down transformer is missing or damaged Centroid sells a step down transformer kit for use with servo motors that are rated below 155 vdc as a maximum. DC Power Supply with Transformer Motor rated at 160 DC or greater do not need a step down transformer.

Power Conversion Examples:

- AC volts IN x 1.41 = DC volts out

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

See this DC Servo motor power discussion for more information.

Schematic is available in the ALLIN1DC Individual Circuit Schematic Set, see Page 5

Documentation & Support

Centroid "Cap and Bridge Combo" Kit - 3 Phase Bridge Rectifier (#10957) Features:

- Easily powers up to six 29 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Preassembled, ready to use

- Commonly used for both new CNC control installations and retrofit upgrades

- Required for countries with 50 cycle power

- For use with Three-Phase step down transformer

Includes:

Three-Phase DC Power generator board with Cap, Diode, Inrush Limited, and Resistor

Power Conversion Examples:

- AC volts IN x 1.41 = DC volts out

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

Note: 117VDC is commonly for use with older DC servos that have around 120 to 140VDC max ratings.

See this DC Servo motor power discussion for more information.

See section B3/B4 of this Allin1DC Schematic for wiring information.

This unit converts 3 phase AC power to DC power for use with the Allin1DC main servo bus power input.

Typical AC input power is anywhere from 70 to 110 volts from the 3 phase step down transformer. AC power input voltage depends on the DC max voltage rating of the servo motor. AC volts IN x 1.41 = DC volts out

See typical hook up schematic here.

- Easily powers up to six 29 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Preassembled, ready to use

- Commonly used for both new CNC control installations and retrofit upgrades

- Works with both 50 hz and 60 hz cycle AC power

- Includes Snubbers on the AC power input side.

Maximum practical AC input voltage = 128 volts AC

Minimum practical AC input voltage = 50

Maximum DC Voltage output = 180 DC volts

Power Conversion Examples:

- AC volts IN x 1.41 = DC volts out

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

Documentation & Support

Centroid "Cap and Bridge Combo" Kit - 220/440VAC (#10767) Features:

- Use for a systems with large DC servos such as 40inlb motors

- Requires a Center tap transformer (Not Included)

- High quality large capacity for smooth DC voltage output

- Preassembled, ready to use

- Commonly used for both new CNC control installations and retrofit upgrades

Power Conversion Examples:

- AC volts IN x .637 = DC volts out

- 200 VAC input yields 127.4 VDC out

- 183 VAC input yields 116.6 VDC out

117VDC is for use with older servos that have around 140VDC rating.

See this DC Servo motor power discussion for more information.

Schematic is available in the ALLIN1DC Individual Circuit Schematic Set, see Page 6

This DC servo main power generator unit is for Large DC servo motor applications.

(Note: For typical knee mill and small bed mill applications the 110/120 volt Centroid DC power generator (#12726) will work just fine, here is the link.)

This unit is designed for systems that already run on 220vac or 440vac for the main input voltage and/or have several large DC axis servo motors (for example 40 in-lb servos on a machining center) This unit has more DC power capacity that the 110/120 volt Centroid DC power generator(#12726)

- Easily powers up to six 40 in-lb DC servo motors

- High quality large capacity for smooth DC voltage output

- Preassembled, ready to use

- Commonly used for both new CNC control installations and retrofit upgrades

- Designed for use with a Center Tap transformer. See typical hook up schematics.

- Allin1DC compatible

Minimum AC input = 100

Maximum AC input = 280

Maximum DC Output = 180 DC volts

Power Conversion Examples:

- AC volts IN x .637 = DC volts out

- 200 VAC input yields 127.4 VDC out

- 183 VAC input yields 116.6 VDC out

Use an input voltage that results in a DC voltage out lower than the rated maximum of the servo motor AND the Allin1DC (180 DC volts max)

Typical hook up schematics:

See this DC Servo motor power discussion for more information.

Schematic is available in the ALLIN1DC Individual Circuit Schematic Set, see Page 6

Documentation & Support

Custom sizes available via phone or email. Add $28.50 for each foot additional conduit length.

Custom sizes available via phone or email. Add $28.50 for each foot additional conduit length.

DC Servo Encoder Cable (#1754) is the same high quality, 22AWG shielded, twisted pair with drain wire used in our pre-built ready-to-use DC servo motor cables. Cable is made with a tough polyurethane jacket. Also Sold per foot: call or email us, $1.25 / foot. Connectors available separately. Made in USA.

DC Servo Motor Power and Encoder Connector Kit (#13017) Includes:

- Qty. 10 Molex Female Terminal Pins

- Qty. 3 Terminal Spade #6

- Qty. 1 Molex .093 3 Pin Socket W/ Lock

- Qty. 4 Molex .093 Female Terminal Pins

- Qty. 1 DB9 Hood

- Qty. 1 Molex 9 Pin C-Grid Housing

Make your own DC servo motor power and encoder cables using this connector kit. connectors for both ends of the cables. Power cable connects to servo motor connectors, power cable connects to Allin1DC. Encoder cable connects to encoder pigtail connector and encoder cable connects to Allin1DC connector.

Motor and Encoder Cable Mating Connectors

DC Servo Motor Power Cable (#1753) is for use with 40 in-lb DC Servos and smaller. This is the same high quality 14AWG shielded wire used in the Centroid Motor/Encoder cable sets. Cable is made with a tough polyurethane jacket. We offer it here for those that want to build their own cables. Also sold per foot: call or email us, $3.25 / ft. Made in USA.

DC Servo Motor Power Supply 110/220 VAC to 117 DC Volt Kit (#10537,#10010) includes

- Step Down Transformer

- Capacitor

- Bridge rectifier board

- Output 117 volts DC

- Input 110/120 VAC single phase

- For use with Servo motors with max voltage ratings higher than 117 VDC

- Commonly used in retrofit upgrades when reusing existing servos that have max voltage ratings in the 120 to 145 DC volt range

- Compatible with the Allin1DC CNC controller

(Note: For DC servo motors with a maximum voltage of 155 volts DC and higher the transformer is not necessary when directly rectifying 110/120 VAC to DC. Use Centroid's Centroid's "Cap and Bridge Combo" DC Servo Motor Power Generator - 110/120 VAC to DC for these cases. )

See typical hookup schematics: S14996

Power Supply Bridge Rectifier (#10674, #10675) is used to rectify AC to DC for Servo Motor Power use.

- Requires a 12,000+ mfd or higher rated capacitor

- Bolts to standard size capacity with 1.125" terminal spacing

- Can also be wired to a capacitor, rather than bolt on

- Use with your own Capacitor

- 600 volts max, with 35 amps rating.

Power Conversion Examples:

- AC volts IN x 1.41 = DC volts out

- 110 VAC input yields 155 VDC out

- 83 VAC input yields 117 VDC out

Designed to bolt to at least a 12,000 MFD 250 Volt Capacitor (larger is ok), this printed circuit board rectifying bridge includes the diode bridge, in-rush limiter, bleed down resistor and terminals for AC power in and DC power out. The distance between centers of the capacitor terminal is 1.125in. 600V, 35A AC in one side, DC power out the other! It couldn't be more simple. Made in USA.

- Emergency Stop Button (#14534) includes:

- 1x E-Stop Button

- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, AcornSix, Allin1dc, Oak, Hickory, and MPU11 CNC control boards.

- Thru Hole Panel Mount

Documentation & Support

- Emergency Stop Button with Snubber Assembly (#14374) includes:

- 1x E-Stop Button

- 1x Snubber for contactor

- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, AcornSix, Allin1dc, Oak, Hickory, and MPU11 CNC control boards.

- Thru Hole Panel Mount

Allows all CNC cabling to enter cabinet through one hole

Download PDF with hole dimensions

Save time and eliminate expensive fussy cable bulk head connectors with this Centroid Electrical cabinet cable entry management system. This invention allows all the CNC cabinet cables to enter the cabinet thru one rectangular hole in the bottom of the cabinet. The system both seals and supports and organizes the cables.

This system eliminates having to drill many holes in the cabinet significantly reducing cable installation labor and connector costs. Also this system make for a more reliable electrical cabinet with less holes in the electrical cabinet that means less chances for dust, chips, dirt , fluids to enter the cabinet and potentially damage the CNC electronics. With this system it is easy to add or remove a cable with no holes to drill or cover up after a cable addition or subtraction. Reusable and resealable any number of times. Installation is easy simply cut one rectangular hole in the bottom on the cabinet and 4 mounting holes and all necessary CNC cables can be installed using this one entry point. Made in USA, Steel construction with Poron sandwich. 10.5" long.

Encoder with pigtail connector. Commonly used to upgrade old existing AC servo motors or added to a new AC servo motor. Replaces Tachometers, Resolvers and Low resolution Encoders. Also used to upgrade existing DC servos to the latest technology for silky smooth closed loop CNC operation.

Centroid stocks these high resolution, 5Vdc, quadrature differential servo motor encoders in 8mm shaft size. Encoder to Encoder cable pigtail included which allows wiring to a mill connector or to a 9 pin C-grid connector for DC applications for compatibility with Centroid Encoder Cables, 8000 RPM maximum. Please measure the servo motor encoder shaft diameter before ordering. More technical how-to information on Encoders here..

- These packages includes:

- 1x Leadshine EL7 EtherCAT Drive

- 1x Leadshine ELM2 Servo Motor

- 1x Encoder Cable

- 1x Power and Brake (if applicable) Cable

These Leadshine EL7 EtherCAT drive/motor/cable packages have been curated by Centroid with extensive testing on various Hickory equipped CNC machine tools at our facility here in Central Pennsylvania USA.

These packages consist of compatible AC Servo Motors, EtherCat Servo Drives and the corresponding Cables you need for your next CNC machine tool project, simply pick the motor size, type and cable length.

- Hickory and these packages provide Absolute Encoder functionality! That means the machine always knows where it is at even when powered off.

- Daily CNC machine homing is eliminated with absolute encoders!

- Any paired axes will always square to each other when powered up.

- Limit and Home switches are optional and unnecessary.

- Daisy Chain connection from Hickory to the EL7 drive and all subsequent drives simplfies cabling installation and reduces both cable and labor costs.

- Utilizes off-the-shelf shielded ethernet cables

USA shipments drop ship direct from the Leadshine USA warehouse in California

International Shipments drop ship direct from Leadshine HQ in China

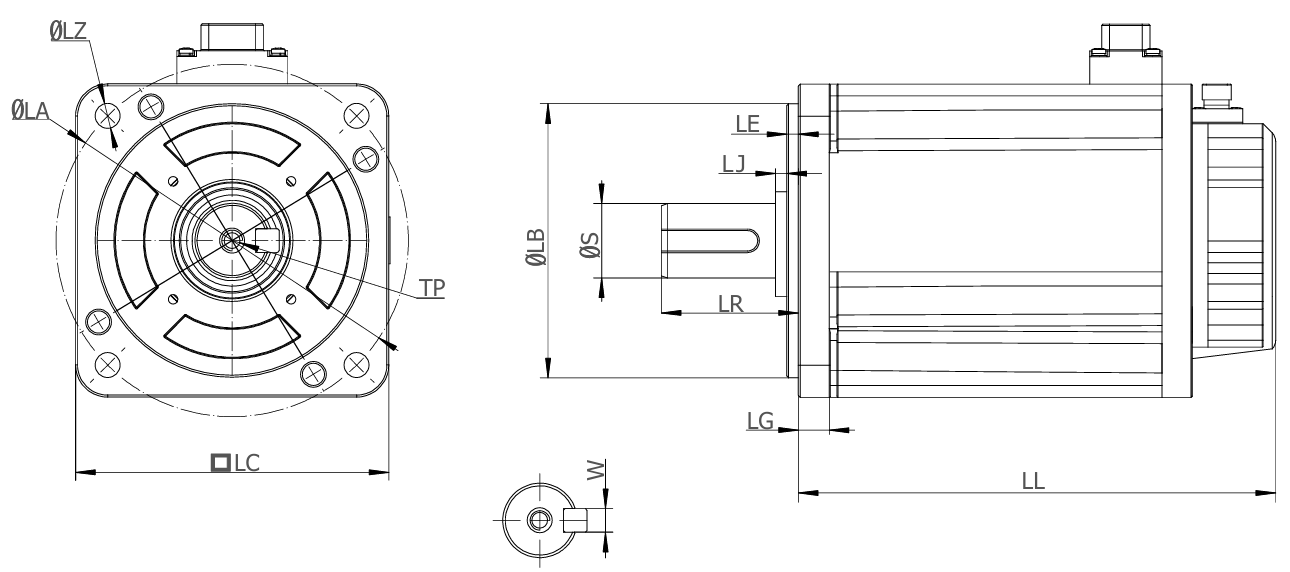

When choosing the motor type note the motor physical size, power rating, useful RPM when sizing to your application.

750 watt (80 mm frame, 3000 rpm, 2.39 N-m cont., 5000 max rpm)

Where the "80 mm frame" refers to the square face frame size of the 750 watt motor. Reference the complete ELM2 servo motor dimensional specifications here.

and the "3000 rpm" refers to the useful, normal RPM range of the 750 watt motor (0-3000)

and "2.39 N-m" is the useful, normal continuous torque output of the 750 watt motor in Newton Meters

and the "5000 max rpm" is the maximum RPM of the 750 watt servo motor, this max rpm can be reached for short periods by the motor as long as the motor load is not excessive. Note: Torque will fall off from the continuous torque rating above the useful RPM, in this example 3000 rpm.

Gear and Size the machine tool kinematics for the desired results (machine max rates, accuracy and power) if in doubt its always best to use the next size larger servo motor/drive package.

Leadshine ELM2 Motor Sizes

| Motor Dimension without Brake (Units: mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage | Motor | LL | LC | LR | LA | LZ | LG | LE | LJ | S | LB | TP | W |

| 200 watt | ELM2H-0200LA60F | 71.6 | 60 | 30 | 70 | 5.5 | 6.6 | 3 | 3 | 14 | 50 | M5x12 | 5 |

| 400 watt | ELM2H-0400LA60F | 88.8 | 60 | 30 | 70 | 5.5 | 6.6 | 3 | 3 | 14 | 50 | M5x12 | 5 |

| 750 watt | ELM2H-0750LA80FT | 90.9 | 80 | 35 | 90 | 6.5 | 8.1 | 3 | 3 | 19 | 70 | M5x12 | 6 |

| 850 watt | ELM2H-0850LD130FT-H | 147 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 5 |

| 1 kW | ELM2H-1000LA80F | 134.9 | 80 | 35 | 90 | 6.5 | 8.1 | 3 | 3 | 19 | 70 | M5x15 | 6 |

| 1.3 kW | ELM2H-1300LD130FT-H | 168 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 6 |

| 1.8 kW | ELM2H-1800LD130FT-H | 195 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 8 |

| Motor Dimension without Brake (Units: mm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wattage | Motor | LL | LC | LR | LA | LZ | LG | LE | LJ | S | LB | TP | W |

| 200 watt | ELM2H-0200LA60E | 100.9 | 60 | 30 | 70 | 5.5 | 6.6 | 3 | 3 | 14 | 50 | M5x12 | 5 |

| 400 watt | ELM2H-0400LA60E | 118.1 | 60 | 30 | 70 | 5.5 | 6.6 | 3 | 3 | 14 | 50 | M5x12 | 5 |

| 750 watt | ELM2H-0750LA80ET | 121.9 | 80 | 35 | 90 | 6.5 | 8.1 | 3 | 3 | 19 | 70 | M5x15 | 6 |

| 850 watt | ELM2H-0850LD130ET-H | 172 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 5 |

| 1 kW | ELM2H-1000LA80E | 103.9 | 80 | 35 | 90 | 6.5 | 8.1 | 3 | 3 | 19 | 70 | M5x15 | 6 |

| 1.3 kW | ELM2H-1300LD130ET-H | 192 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 6 |

| 1.8 kW | ELM2H-1800LD130ET-H | 219 | 130 | 55 | 145 | 8.5 | 17.5 | 4 | 0.5 | 22 | 110 | M6x20 | 8 |

If you are purchasing a new Acorn kit, you do not need to purchase this item.

This Adapter kit is for early Acorn Boards sold in 2017 and 2018.

The Legacy Acorn Relay Board Kit (#15289) Includes:

1x Acorn “8 Relay Module”

1x Ribbon Cable

1x Acorn Relay Adapter Card with 5 vdc pig tail.

More Information Available Here

Legacy Acorn_rev3 CNC Controller Specifications Manual

This kit will convert Acorn’s six open collector outputs into Relay Outputs in under a minute. The kit uses an off the shelf SainSmart “8 Relay Module” combined with Centroid’s Relay Module Adapter Card and a ribbon cable for easy installation. The adapter card simply inserts into the Acorn Output Connector header screw terminals. Powered by 5 Volts DC the Adapter card comes with a pre-installed 5 VDC pig tail which connects to the 5 VDC terminal on the Acorn Logic Power supply. This allows CNC controlled connections to various CNC devices such as VFD’s, solenoids, lights, fans, pumps, motors, other larger relays and contactors in a compact format. The 8 relay module contains eight SPDT (Single Pole Double Throw) high current relays (10 AMPS at 250 VAC, and 10 amps at 30 VDC) which can directly control any device rated at or below the maximum rating of the relays. If higher current devices are required these relays can then in turn control larger relays or contactors to control the higher current device.

Oak Board to Servo Drive Cable (#13134, 13131, 15236, 13133) is a communications cable that connects a servo drive to the Oak CNC controller. One end plugs into the servo drive, and the other end plugs into the Oak CNC control board. Sold in 4 variations.

1.) Yaskawa. Works with Yaskawa Sigma 1,2,5,7 Servo drives

2.) Delta ASD-A or ASD-AB

3.) SureServo2

4.) Flying lead. Servo drive end of cable is left "flying lead" so user can mount any kind of connector necessary to connect to a drive other than Yaskawa, Delta or SureServo2

*Yaskawa cable shown

Compatible with:

Operator Console Arm Hardware Kit

- Mounts Console to Machine Tool

- Swivel joints at both ends

- Top or Bottom console mount

- Flexible mounting options at Machine end

- Heavy Duty Steel Construction

- Smooth 90 degrees console swivel rotation

- Through Arm control cables chase

- Integral Left/Right Level Adjustment

- Optional Utility Tray and Mouse tray

- Made in USA

Make your own Console mounting hardware or purchase ready to go CNC console mounting hardware kits!

Operator Console Floor Stand

- Adjustable Console Height and Angle Articulation

- Vesa Standard 200mmx200mm mount

- Heavy Duty Steel Construction

- Locking Floor Casters

- Optional Utility Tray and Mouse tray

- Shown with Optional Utility Tray, Optional Mouse Tray, and Wired MPG (sold separately)

This is the optional Mouse Tray for the Centroid Operator Console Floor Stand. This item can be purchased with the Operator Console Floor Stand but is available separate as a replacement or for those who want to mount it to their Console Keyboard Tray. Click here for mounting examples.

This is the optional Utility Tray for the Centroid Operator Console Floor Stand. This item can be purchased with the Operator Console Floor Stand but is available separate as a replacement or for those who want to mount it to their Console Keyboard Tray. Click here for mounting examples.

Choose between two stock lengths, 12 foot and 16 foot. These cables use twisted pair made-in-USA wire and are properly shielded and grounded for reliable encoder signal and are built and assembled by Centroid in the USA. (If a longer cable is required, we suggest purchasing the bulk encoder cable)

These cables are commonly used when upgrading DC servo motor encoders for use with the Allin1DC CNC controller. These cables can also be used for spindle encoder applications on both the Allin1DC and Acorn CNC controllers. One end of the cable is a DB9 connector which plugs directly into the Allin1DC or Acorn CNC controller, the other end of the cable is a single row flat pin connector (9 pin C-grid connector) which plugs into the Centroid Encoder pig tail mating connector.

A mating 9 pin C-grid connector and pins are optional with this cable for the case when a non-Centroid encoder is used. The optional mating 9 pin C-grid connector can be installed on the non-Centroid encoder pig tail wires which then allows the encoder to plug directly into this cable with no soldering or cutting of this cable.

Plug and Play Centroid DC Servo Motor Power and Encoder Cable (10694)

Custom Lengths over 20' available on a made to order basis add $7 per foot for custom cable price over 20'. Call or email diysales@centroidcnc.com.

Typically used for replacement or retrofit upgrade of an existing DC servo motor for use with the Allin1DC CNC controller. You can make your own cables or buy these ready to go units to save time. High quality Cable with Polyurethane jacket, Color coded encoder cable is twisted pair with Shield and Drain for proper noise immunity. Power cable is high quality stranded copper with proper terminals at both ends for plug and play use with the Allin1DC. Both cables have thick rubber liquid tight strain relief seal at the motor end.

Compatible with:

This cable is used to connect the AcornSix or Hickory board to a Probe bulkhead connector. This cable comes 'flying lead' and includes an inline fuse.

This cable is used to connect the Allin1DC or Oak board to a Probe bulkhead connector

Quencharcs (#1819), aka "Snubbers", are a critical component noise suppression device that is required on all Contactors, Solenoids and external Relay coils.

Contactor in photo not included, Image shows typical Installation of Quencharc across a contactor coil.

Minimum Order Quantity of 3

Designed for noise suppression of all contactor, solenoid and relay coils to prevent interruption of CNC control communications. One Quench arc should be installed across each coil used in any CNC system.

Contactor in photo not included, Image shows typical Installation of Quencharc across a contactor coil.

Quencharcs are commonly used on all sorts of accessory coils, such as Flood Pump, Mister Solenoid, Vacuum Solenoids, Dust Collection motor starters, Estop Contactors and any other device controlled by a Contactor, Relay or Solenoid.

See our Tech Bulletin on how to use Quencharcs (aka Snubbers) for Noise Suppression.

If you are purchasing a new Acorn kit, you do not need to purchase this item.

The Acorn Relay Board Kit (#14734) Includes:

1x Acorn “8 Relay Module”

1x Ribbon Cable

CNC Operator control panel (#14612)

If you like pressing buttons rather than touching a screen use this tough Centroid Operators control panel. Its made in USA and uses stainless steel dome buttons that provide positive tactile feedback. Constructed of steel the bezel can mount into pendant box or flush to any cut out. The high quality overlay made from durable grease and chemical resistant special flexible plastic designed for the machine shop environment. Use as a replacement for the VCP (virtual control panel (touch screen)) OR use in conjunction with the VCP. The VCP and the control panel are user configurable so they can be setup to match functionality.

The operator panel can be installed several different ways:

1.) Mount in a CNC console

2.) Machine Panel Mount (console is part of the machine tool)

3.) Corded Hand Held with 16' cord, steel construction, rubber handles and magnets on the back.

A lower cost ($0) alternative to this piece of hardware is the software based Touch Screen Virtual Machine Control Panel (VCP). The VCP allows the functionality of this Hardware based Operators Control Pendant when using a Touch Screen LCD as the CNC control display. The touch screen VCP is included with Centroid CNC control software CNC12 and can be used without or in conjunction with this hardware based Operator's Control Pendant.

Longer cords up to 50' are available call for quote or just use the Wireless MPG for long distance applications

Compatible with:

AcornSix Scout Encoder Expansion Kit (# 15330) Features:

- Add six additional Encoder or Scale ports to an AcornSix

- Plug and Play, Encoder Expansion board to AcornSix uses a standard shielded ethernet cable (included)

- Typically used for multiple MPG or Scale inputs.

- User configurable

The Centroid AcornSix Scout Encoder Expansion Kit adds six additional encoder/scale/mpg ports for a total of nine to a AcornSix based CNC controller. The additional encoders ports can be used for encoder input, scale input, and MPG input. Connects to the AcornSix via a standard shielded Ethernet cable which is included. Scale input with the AcornSix can be used as a DRO position readout OR for closed loop position correction.

| Encoder Type | Rotary Encoder | Linear Scale | MPG Handwheels |

|---|---|---|---|

| A/B differential quadrature (W/ Index Pulses) |

Yes | Yes | No |

| A/B differential quadrature (W/O Index Pulses) |

No | No | Yes |

| BiSS B/BiSS C Serial Encoders | Yes | Yes | No |

Compatible with:

Documentation & Support

Servo Motor Upgrade Encoder Kit (#3403, 4127, 2848, 4655, 14442, 14368, 15588)

Commonly used to upgrade old existing DC servo motors to be compatible with the Centroid Allin1DC. See example servo motor encoder upgrade here. Replaces Tachometers, Resolvers and Low-resolution Encoders. Upgrade existing DC servos to the latest technology for silky smooth closed loop CNC operation. Centroid stocks these high resolution, 5vdc, quadrature differential encoders in several commonly found shaft sizes. Encoder to Encoder cable pigtail included which allows plug and play compatibility with Centroid Encoder Cables, no crimping or soldering needed. Please measure the servo motor encoder shaft diameter before ordering. Find more technical how-to information on Encoders here.

To reduce unwanted noise and connection issues, a SHIELDED ethernet cable must be used between the CNCPC and the CNC control board.

We are now offering standard lengths up to 50' of Shielded Ethernet Cables to our customers who have longer runs between their CNCPC and CNC Controllers.

Product may vary from image shown. Cables may come as Cat5e or Cat6a, depending on our supplier's stock.

Having communication issues with your CNCPC and CNC Control Board? Check this Free Support Forum Thread for help!

Step-Down Transformer – 440/220VAC to 110VAC + 24VAC (500VA) (#4953) Features:

- Converts high voltage (440V or 220V) to 110V and 24V for control circuits

- 500VA capacity – ideal for industrial control panels and CNC retrofits

- Built with high-grade insulation for long-lasting performance

- UL, CSA, and CE certified for global compliance and safety

Note: This transformer is rated for 480V/240V input but is compatible with nominal 440V/220V systems

Wired MPG (#11069) Features:

- 100 pulses per rev

- Axis Selector for 6 axes

- Increment amount selector (user configurable in CNC10/11/12)

- For use with Allin1dc and Oak CNC control boards.

- High quality construction with gold plated connector pins

- Hook hanger mount and magnets on the back of the unit

- Pre configured for use with Centroid CNC10/11/12 control software

- Plug and Play with Oak/Allin1DC cnc controls running CNC11 or CNC12 software

Looking for an MPG for an older CNC10 system? Please email us your system serial number.

CNC10 Kits numbers had 5 digits (Note: if you have a 6 digit Kit number that is a CNC11/CNC12 system).

How to locate serial number

Use the Manual Pulse Generator to jog the machine tool, very useful for part and tool setups. Order with or without internal bulk head cable. If you have a factory built M400/T400 CNC control or if you ordered the CNC console conduit cable kit you do not need to buy the internal bulkhead cable. If you are building a DIY CNC control based on the Oak cnc controller you will need the internal bulkhead cable to connect this MPG to the Oak or Allin1DC board.