Centroid Acorn CNC Controller

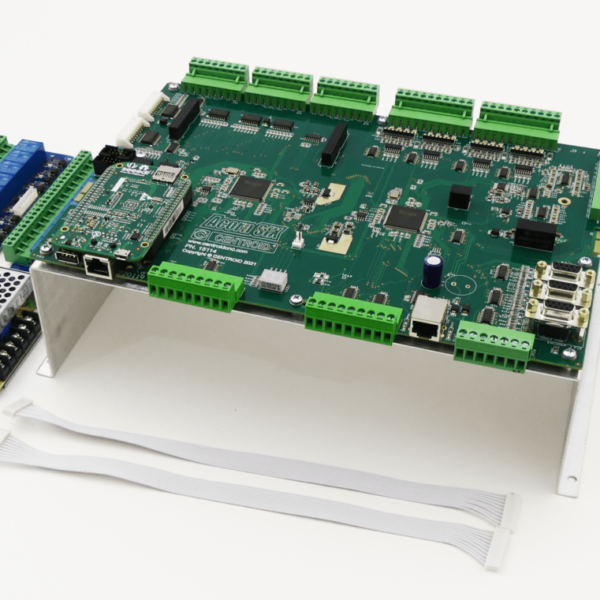

Acorn CNC control kits are both a CNC Hardware and CNC Software DIY system designed to work together for easy CNC setup and operation with minimal fuss.

$369.00

Estimated Shipping Date

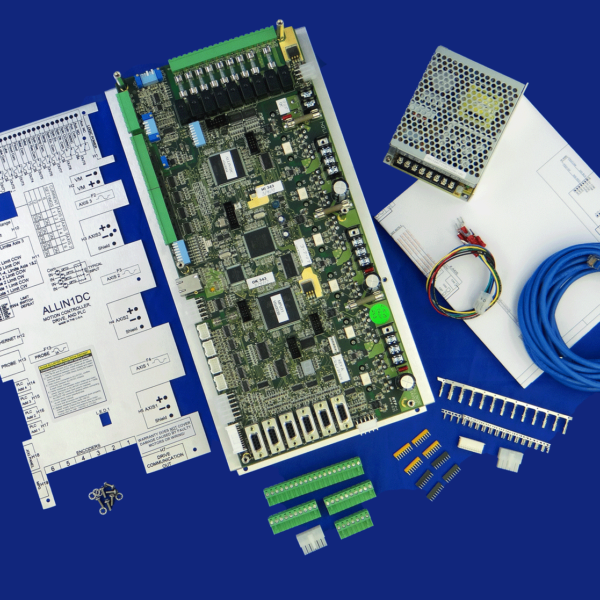

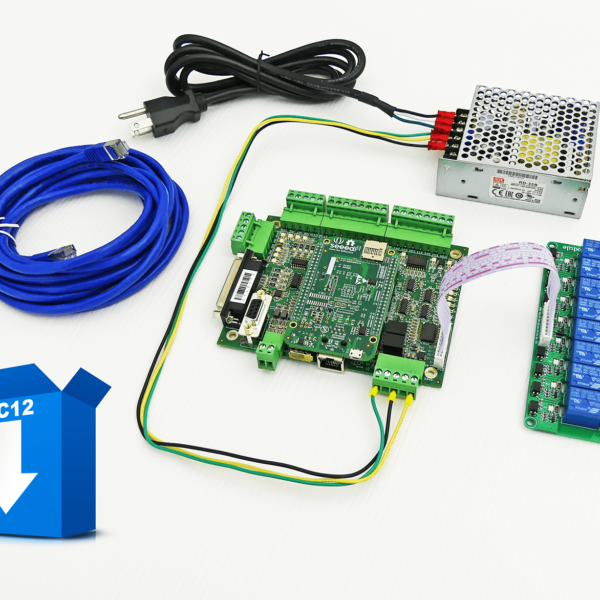

- Centroid Acorn CNC controller kit (#14455) includes:

- 1x Acorn CNC control board

- 1x Acorn Plug and Play Relay8 Module

- 1x Dual power 5 VDC and 24 VDC logic power supply

- 50/60 Hz 100-120 VAC/208-240 VAC input power

- 1x Logic power supply hookup leads

- 1x 110 VAC power cord

- 1x 15’ Shielded Ethernet cable

- 1x Plexi Acorn Cover

- 4x 6-32x3/4" Standoffs for Acorn Cover

- 4x 6-32x3/8" Screws for Acorn Cover

- Additional Acorn highlights:

- Comes with Centroid CNC12 "Free" CNC Software Download, Pro and Ultimate Software sold separately

- Touch Screen Responsive Operator Controls

- DIY self-service CNC support thru Centroid Community CNC Forum which is Centroid Technician monitored and maintained.

- Optional Factory Direct Technical Support: $120/hr.

(Note: A 1920x1080 wide screen LCD Display is required and a Touch Screen is recommended.)

Damaged or Dead board? We can help with that! Acorn Swap-out Program is available here!

Email diysales@centroidcnc.com or call 814-353-9256 ext 122

M-F 9-5 EST to place your orders.

|

- Acorn "Start Here" Web Page with requirements and How-to Videos

- Acorn CNC controller Hookup Schematics (type in Acorn in the search bar on this page to see all Acorn hookup schematics)

- All Acorn Documentation (a list of All Acorn related documentation)

- CNC Community Support Forum (Free Tech Support!)

- Acorn CNC controller buyers FAQ

- Centroid Free CNC Mill and Lathe Software Download (a powered up Acorn is required to run the CNC software)

- Current Mill Manual

- Current Lathe Manual

- CNCPC Requirements

- Centroid Solid (.stp) Models

-

Can I buy one Pro Acorn CNC12 license and use it on several Acorn CNC control boards?

No, the Centroid Acorn Pro and Ultimate licenses are tied to the Acorn board serial number. When purchasing a Pro or Ultimate license, the Acorn serial number is required and then a Pro or Ultimate license is created that matches the Acorn board serial. When the CNC12 software starts, it checks the Pro or Ultimate license against the Acorn board that is connected to the CNCPC for a match. If it matches, then that particular level (Pro or Ultimate) of CNC12 software is made active. If it doesn't match, then the CNC12 software runs at the "Free" level. (So Acorn CNC12 will run without any license installed)

-

If I buy an Acorn Mill Pro CNC12 license and then decide to upgrade to an Ultimate license how much does that cost?

$225

-

Can I buy an Acorn Mill Pro and Acorn Lathe Ultimate for use on the same Acorn Board?

Yes. You can mix and match any license with the Acorn CNC Control Board. You can run Acorn Router Pro and Acorn Plasma Ultimate on the same Acorn but not at the same time.

-

Can I ask Centroid to move a Pro or Ultimate software License from one Acorn board to another?

If Centroid issues an RMA for an Acorn board to be returned, any License associated with that board can be transferred to another Acorn board.

-

Do I have to state at time of purchase what machine I plan on using the Acorn with?

No. The Mill, Lathe, Router, and Plasma Free versions of Acorn CNC12 control software are available for download so you can configure the Acorn controller for a wide variety of machine tools. The hardware doesn't care what kind of machine it connected to :-)

-

If I bought an Acorn Mill Pro License, can I use it with the Acorn Lathe Software?

No. The Acorn Pro licenses are version specific. There is a Pro license for Mill, Lathe, Router, and Plasma. Each version of software also has an Ultimate version as well, with additional features. Please see the Feature Comparison table here.

-

If I destroyed the BBG (Beagle Bone Green) that came with my Acorn board can I supply my own?

Yes, but the License file(s) that were issued for that Acorn will not work with the new BBG. Centroid offers License transfer service for $29 which requires you to email us a report.zip file to diysales@centroidcnc.com. Information on how to generate a report.zip file is here.

-

How big of a G-code program can I run with the Free version of CNC12 Mill, Lathe, Router, and Plasma software?

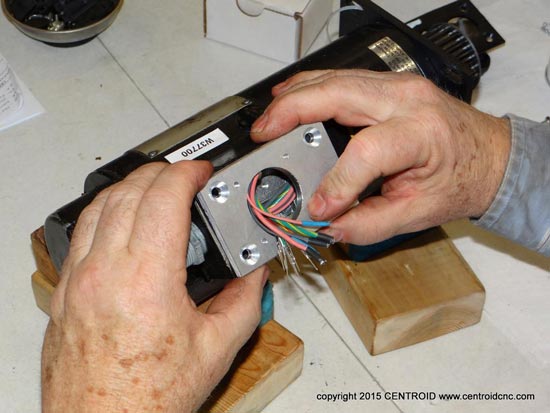

50Kb for Mill, Router, and Plasma. 5Kb for Lathe..To give you an idea of what can be done with the Free version of the Acorn CNC12 software: on our website is a part program for a SEM DC servo motor cover plate, below on the left is the plate being installed and on the right is the tool path that was used to make the cover plate. This G code program to make this part is 5Kb in size. This is pretty typical of a home hobby shop type part. The G code file generated by a cad cam system or in this case Centroid's Intercon conversational programming software (with comments!) to make this part the G-code program is only 5kb in size. The Centroid FREE version of CNC12 has a file size limitation of 50KB so you could run a G code program 10 times this size with the Free version of CNC12. As you can see, you can do a lot even with the Free version of the Acorn CNC12 software.

The 5kb Gcode program used to cut this SEM servo motor cover plate is available here (click to view, right click link and Save as to download).

Note: The Centroid PRO version of CNC12 has no file size limitation so you could run a file as large as the hard drive on the CNCPC and the Ultimate License also has no file size limitation. (only limited by the size of the CNCPC hard drive space)

-

How long does it take to ship the Acorn CNC control kit?

Typically the Acorn CNC control kits are in stock ready to ship and ship within one or two business day from Howard, PA. You will receive an email with tracking number when your kit ships.

-

Do I have to have a paypal account to order a Acorn Kit?

No. Add items to the cart with the add to cart button and then select "Credit Card" at Checkout.

-

Can I order an Acorn CNC control kit over the phone? And do you have resellers in the EU?

Yes. Centroid accepts orders for Acorn kits through our website and phone, and will accept bulk orders (5+) via email but website is the preferred method. We do ship internationally! International shipping will be calculated after the sale typical Air Freight cost range in the $70 to $120 for typical Acorn kit international orders. Alternatively, below a list of other locations to purchase the Acorn CNC controller.- USA

- International

-

Do you have a list of drives that Acorn works with?

The Acorn CNC controller commands many different types of servo and stepper motor drives with industry standard "Step and Direction" drive communication signals. Any drive that accepts Step and Direction is compatible with the Acorn CNC Controller. The list of known compatible drives is too long to list so we've highlighted a few here:- Yaskawa

- Delta

- Estun

- Teknic Clearpath

- Gecko

- Leadshine

- Teco

-

How do I contact Technical Support?

Free Acorn Technical Support is available 24/7 on the Acorn CNC community support forum. Here is how to sign up for the Free Support Forum. Centroid Direct Technical Support is available for $120/hr. one hour min. You can purchase support here then email support@centroidcnc.com with a current Report.zip file.

-

Do I need to purchase a PC from Centroid or can I build my own?

Ready to run Centroid CNCPC's are avalible for sale from Centroid, alternatively you can supply your own CNCPC as long as it meets the Centroid Minimum PC performance specifications found here.

-

What is the Acorn Return, Warranty and Repair policies?

Please see this page for complete details.

-

Is there a return restocking fee?

Yes. There is a 15% restocking fee on all returned parts and products.

Centroid Mill CNC Software Licenses

Price range: $179.00 through $399.00

- License Version Upgrades will be provided free of charge for major versions released within 12 months of your original CNC main board (Acorn, AcornSix, Hickory, Allin1DC, Oak, MPU11) purchase.

- Licenses purchased within 30 days of a major version release are eligible for a free Version Upgrade to the next version.

- More information about the new CNC12 License Version Schema can be found here.

Once a software license has been assigned to a control, it becomes non-transferable with the exception of RMAs. After a software license has been generated it is non-refundable and can not be exchanged for another version of Software unless you are upgrading from Mill Pro to Mill Ultimate. Please see the Acorn FAQ for more information.

Please see the detailed table below describing the differences between Pro and Ultimate software levels

Centroid Lathe CNC Software Licenses

Price range: $179.00 through $399.00

- License Version Upgrades will be provided free of charge for major versions released within 12 months of your original CNC main board (Acorn, AcornSix, Hickory, Allin1DC, Oak, MPU11) purchase.

- Licenses purchased within 30 days of a major version release are eligible for a free Version Upgrade to the next version.

- More information about the new CNC12 License Version Schema can be found here.

Once a software license has been assigned to a control, it becomes non-transferable with the exception of RMAs. After a software license has been generated it is non-refundable and can not be exchanged for another version of Software unless you are upgrading from Lathe Pro to Lathe Ultimate. Please see the Acorn FAQ for more information.

Please see the detailed table below describing the differences between Pro and Ultimate software levels

Centroid Router CNC Software Licenses

Price range: $179.00 through $399.00

- License Version Upgrades will be provided free of charge for major versions released within 12 months of your original CNC main board (Acorn, AcornSix, Hickory, Allin1DC, Oak, MPU11) purchase.

- Licenses purchased within 30 days of a major version release are eligible for a free Version Upgrade to the next version.

- More information about the new CNC12 License Version Schema can be found here.

Once a software license has been assigned to a control, it becomes non-transferable with the exception of RMAs. After a software license has been generated it is non-refundable and can not be exchanged for another version of Software unless you are upgrading from Router Pro to Router Ultimate. Please see the Acorn FAQ for more information.

Please see the detailed table below describing the differences between Pro and Ultimate software levels

Centroid Acorn CNC Mill, Router and Lathe Software Levels

| Features | Acorn Free v5.40+ | Acorn Pro v5.40+ | Acorn Ultimate v5.40+ |

|---|---|---|---|

| Mill and Lathe Intercon Conversational programming | Limited to 20 blocks of conversational | Unlimited | Unlimited |

| Wireless MPG Pendant WMPG-4 or WMPG-6 support | Not included | Included | Included |

| G-code program size | Limited to 50Kb G-code file size (Mill, Plasma, Router) Limited to 5Kb G-Code file size (Lathe) |

Unlimited G-code file size | Unlimited G-code file size |

| Work Coordinates Systems (WCS) | One (G54) | Eighteen (G54-G59 plus extended WCS) starting with v5.08 | Eighteen (G54-G59 plus extended WCS) |

| Menu driven Probing cycles | Center of bore | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR | Complete Set of menu driven probing cycles. Bore, Boss, Slot, Web, Inside Corner, Outside corner, Single edge find, find angle, auto probe for CSR |

| Menu driven Digitizing cycles | Grid, Radial, Contour, Wall following, limited to 2500 points | Grid, Radial, Contour, Wall following, limited to 2500 points | Unlimited point Grid, Radial, Contour, Wall following |

| Auto Tool Height Measurement | Unlimited auto measure on: Reference Tool & Tools 1,2,3 |

Unlimited auto measure on all tools. |

Unlimited auto measure on all tools. |

| Coordinate System Rotation | Yes | Yes | Yes |

| Auto find CSR with Probe | No | Yes | Yes |

| Manual find CSR with Probe or Wiggler | Yes | Yes | Yes |

| Manual enter angle for CSR | Yes | Yes | Yes |

| Tool Library | 10 Tools | 200 Tools, (99 Tools Lathe) | 200 Tools Mill, (99 Tools Lathe) |

| Sub Programs and Macros (M98 & G65) Write your own custom macros, many uses |

Included | Included | Included |

| Cutter Compensation G41/G42 | Included | Included | Included |

| Backlash Compensation | Included | Included | Included |

| Screw compensation (laser or manual!) | Included | Included | Included |

| 3 axis simultaneous | Included | Included | Included |

| 4 th Axis linear or rotary conversational programming. | limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Operate as a 2 axis CNC with Manual Quill | Included | Included | Included |

| Operate as a 2 or 1 axis CNC control | Included | Included | Included |

| Any axis can be Linear or Rotary | Included | Included | Included |

| Supported Axes Labels | X,Y,Z,U,V,W,A,B,C Mill/Router/Plasma |

X,Y,Z,U,V,W,A,B,C Mill/Router/Plasma X,Y,Z,C,A,B Lathe |

X,Y,Z,U,V,W,A,B,C Mill/Router/Plasma X,Y,Z,C,A,B Lathe |

Spindle Encoder feedback,w/ RPM display |

Included | Included | Included |

| Mill Rigid Tapping | Not Included | Included | Included |

| Lathe Threading | Not included | Included | Included |

| Lathe Automatic CSS | Not Included | Included | Included |

| Lathe Rigid Tapping | Not included | Included | Included |

| Lathe C-Axis (M51) | Not Included | Not included* | Included |

| Lathe Automatic Tool Measurement | Unlimited auto measure on: Tools 1,2,3 |

Unlimited auto measure on all tools. | Unlimited auto measure on all tools. |

| G81 drilling cycles | Included | Included | Included |

| Compression Tapping Gcode Cycles | Included | Included | Included |

| Mill G-code scaling and mirroring | Included | Included | Included |

| True G-code backplot graphics | Included | Included | Included |

| Run Time Program Graphics | Included | Included | Included |

| Smart Search (stop and restart at any point) | Included | Included | Included |

| User Configurable Touch Screen Virtual Control Panel | Included | Included | Included |

| Backlash compensation | Included | Included | Included |

| CNC Configuration Wizard | Included | Included | Included |

| Menu driven Part and Tool setup menus | Included | Included | Included |

| Intercon Teach Mode | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Drilling cycles: Drilling, Deep Hole, Chip Breaking | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Pocketing: Circular,Rectangular, Irregular | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Contouring | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Threadmilling | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Conversational Compression Tapping | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Auto Connect Radius | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Lathe Cycles. Auto profile cleanout, grooving, cutoff, chamfer, turning, end face turning, | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon Math/Geometry Help | Limited to 20 blocks of Intercon | Unlimited | Unlimited |

| Intercon DXF Import for Mill and Router. | Yes, Limited to 20 blocks of Intercon | Yes, MILL, Router, Plasma only | Yes, Mill, Router, Plasma only. |

| Operate in Millimeter or Inches | Yes | Yes | Yes |

| XY Diagonal Jogging | Yes | Yes | Yes |

| 4th axis Jogging | Yes | Yes | Yes |

| Software Axis Pairing (pair 4th axis any other axis in software) |

No | Yes | Yes |

| Auto Squaring of Software Paired axis with auto homing | No | Yes | Yes |

| Hardware Axis Pairing | Yes | Yes | Yes |

| 4th axis G-code moves: 4&1,4&2,4&3,4&1&2,4&2&3,4&1&3&4, 4&1&2&3 |

No, "Free" is limited to 3 axis simultaneous moves with single axis 4th axis moves. (aka (3+1) |

Yes, 4 axis simultaneous movement with full interpolation. (move any axis in combination with any others) |

Yes, 4 axis simultaneous movement with full interpolation. (move any axis in combination with any others) |

| ATC (BCD) Tool Changer Output | No | Included | Included |

| ATC Programs for Rack Mount | No | Yes | Yes |

| ATC Programs for Lathe Turret | No | Yes | Yes |

| CNC Setup Wizard with auto PLC program generation |

Included | Included | Included |

| PLC Detective Software | Included | Included | Included |

| Use one input for all axis Homing | Included | Included | Included |

| Laser Engraving | Yes | Yes | Yes |

| PWM output for Laser power | Yes | Yes | Yes |

| PWM output for Spindle speed control | Yes | Yes | Yes |

| Laser power Velocity modulation | Yes | Yes | Yes |

| 0-5 VDC or 0-10 VDC analog output | Yes | Yes | Yes |

| Support for "Probe App" by swissi | No | Yes | Yes |

| Wireless Touch Probe Support | No | No | Yes |

Email diysales@centroidcnc.com for Details. Note: This offer is valid from 11/25/2024 until 11/25/2025.

Acorn Videos

CNCPC Options: Buy Centroid Configured, or supply your own!

$1,350.00

- All-in-one Touch Screen CNCPC (#15021,15022) Features:

- - Pre-loaded with Windows 10/11

- - Pre-configured for CNC PC duty

- - Pre-loaded with Centroid CNC software

- CNC12 'Free' Level of Selected Preinstalled Software Version

- G code Editor

- Intercon

- Stock PLC programs

- Touch Screen Operator Control panel

- Acorn Install Wizard

- - Touch Screen

- - Wifi, Ethernet, webcam with mic, card reader, USB ports

- - Powercord, Keyboard, Mouse

- - Centroid tested and pre-qualified to work with Centroid CNC controllers

- NOTES:

- Model, Specifications and COLOR may vary.

- There are NO VESA mounting holes on this unit.

The Centroid ALLIN1PC comes pre-configured for CNC Duty. It's ready to use and communicate with our Controls. The PCs run Windows 10/11 and are equipped with a Touchscreen. Product may vary from image.

Planning to build or use your own PC as a CNCPC?

Be sure the PC meets the Centroid CNCPC minimum requirements found here.

The Centroid CNC software runs on any Windows 10/11 PC that meets the requirements.

- If you plan to build your own CNCPC follow the requirements and recommendations here.

- If you plan to buy your own PC, we recommend the Asus (formerly Intel) NUC or the Beelink MiniPC series (be sure to purchase a NUC that meets the Centroid minimum pc requirements) and a 1920x1080, 16:9 aspect ratio, Touch Screen monitor

$799.00

- Centroid Mini CNCPC kit (#15023) includes:

- 1x Intel based Mini PC

- 1x Centroid Aluminum CNCPC Multi-mount Plate

- 2x M3x6 screws to mount the Mini PC to the included plate

- 1x 100-240 VAC power brick

- 1x Pre-installed and pre-configured SSD

- w/ Windows 11 (64-bit)

- w/ CNC12

- Centroid Mini CNCPC (#15023) Features:

- - Use a LCD monitor (not included), 1920x1080 recommended, Touch Screen supported but not required

- Preloaded with a licensed copy of Windows 11. Windows is pre-configured for CNC PC duty!

- Preloaded Centroid CNC12 software Mill, Router, Lathe, and Plasma 'Free' version

- Preconfigured with Centroid Software

- Preconfigured Notepad ++ G code Editor

- Mill, Lathe, Plasma Intercon Conversational compatible

- Centroid CNC setup Wizard (Acorn, AcornSix, Hickory)

- Touch Screen Operator Control compatible

- Intel processor and SSD (solid state drive)

- HDMI, Ethernet Ports, USB

- Includes Power cord. (Monitor, Keyboard, and Mouse are not included)

- Centroid tested and pre-qualified to work with Centroid CNC controllers

- NOTES:

- Model, Specifications and COLOR may vary.

Compatible with:

Acorn Compatible Accessories

$329.00

-

A CNC machine tool operator control panel interface board that connects to the CNCPC via a USB port. The Operator Control Panel Interface Board is intended to be an affordable, reliable, alternative to traditional methods of building CNC control operator control consoles/panels. The USB-BOB provides inputs for the most commonly used operator controls in a package that installs quickly with minimal fuss saving on wiring/installation labor and CNC controller inputs. It features inputs for three standard rotary encoders with integrated push-button, three MPG hand-wheel encoder inputs, 12 optically isolated switch inputs, and 12 open collector LED outputs. The USB-BOB can be used in conjunction with Centroid’s popular Virtual Control Panel or without.

- Centroid "USB-BOB" kit (#15380) includes:

- 1x Made in USA Centroid USB Operator Control Panel board

- 3x Feed Knob Assemblies with cables

- 3x 10-pin Terminal Blocks

- 4x 5-pin Terminal Blocks

- 1x 6' Right-Angled USB to Micro USB Cable

- 4x 6-32x1/2" Standoffs

- 4x 6-32x3/8" Screws

- 4x 6-32 Lock Washers

The Made in USA Centroid USB Operator Control Panel Interface Board (aka “USB-BOB”) is a Made in USA CNC machine tool operator control panel interface board that connects to the CNCPC via a USB port. The Operator Control Panel Interface Board is intended to be an affordable, reliable, alternative to traditional methods of building CNC control operator control consoles/panels. The USB-BOB provides inputs for the most commonly used operator controls in a package that installs quickly with minimal fuss saving on wiring/installation labor and CNC controller inputs. It features inputs for three standard rotary encoders with integrated push-button, three MPG hand-wheel encoder inputs, 12 optically isolated switch inputs, and 12 open collector LED outputs. The USB-BOB can be used in conjunction with Centroid’s popular Virtual Control Panel or without.

The USB-BOB is plug and play with preprogrammed button and knob functionality: Many common functions like Cycle Cancel, Tool Check, Feed Hold and Cycle Start along with Rapid Override, Spindle Speed Override and Feedrate Override are preprogrammed and user select-able with easy drag and drop installation.

In addition to these pre-programmed controls, all controls are user configurable through Centroid’s CNC PLC language so user can customize both the button or knob functionality to suit their application and tastes.

Common uses:

• Physical buttons and knobs for core/common operator functions simplifying the design for a hard operator console

• Supplement Centroid Virtual Control Panel with physical controls without using up any CNC control board inputs

• Add separate Rapid Override to Centroid Legacy control systems that did not have this feature.

Centroid "USB-BOB" Operator Control Panel Interface Manual

USB-BOB is compatible with CNC12 Mill, Lathe, Router, Plasma v5.20+ and is drag and drop super easy customizable using the Acorn, AcornSix, and Hickory Wizard.

When using the USB-BOB with the Centroid Allin1DC and Oak CNC control platforms there is no setup Wizard (like Acorn, AcornSix and Hickory), the USB-BOB is compatible with the Centroid Allin1DC and Oak CNC control platforms and is supported through a few CNC12 parameters (to let CNC12 know to look for a USB-BOB) and then the Centroid PLC program handles all the rest of the inputs and outputs for the USB-BOB. Note: For the Allin1DC and Oak it is required to edit the Allin1DC or Oak CNC controller PLC program to match your custom inputs and outputs of the USB-BOB and then compile it. The Centroid PLC source code is human readable, open source and the compiler and even a debugger is all available for free. Instructions on how to edit and compile Centroid PLC programs are published and we also offer the PLC program modification as a service (purchase here) if you don't want to do it yourself.

Compatible with:

$329.00

- Ether1616 I/O Expansion Kit (#14850) includes:

- 1x Ether1616 Board

- 2x Relay 8 Modules

- 2x Keyed Ribbon Cables

- 1x 24 volt DC power supply

- 50/60 Hz 100-120 VAC/208-240 VAC input power

- 1x Ethernet Switch

- 2x 6’ Shielded Ethernet cable

- 4x 220 Ohm SIP resistors for 5 volt input

- 4x 1k Ohm SIP resistors for 12 volt input

The Ether1616 is an input and output expansion board designed to be used with the Acorn CNC controller. Each Ether1616 board adds an additional 16 optically isolated inputs and 16 relay isolated outputs to the Acorn CNC system, up to three Ether1616 boards can be added to an Acorn system for a total of 56 inputs and 56 outputs. Three different input voltages can be used: 5 volts, 12 volts and 24 volt. Input voltages are mix and match capable and are selectable via bank of four of inputs at a time with the provided plug-in SIP (Single In-line Pack) resistors. The default input voltage is 24 VDC.

Both the Ether1616 and Relay 8 modules provide both Din Rail mounting holes and Standoff mounting holes to allow the DIY installer a wide variety of mounting possibilities!

The provided dedicated power supply is sized properly to provide enough power to drive the 16 relays. There are indicator LED’s on Ether1616 Inputs and on the Relay 8 Modules that indicate the state of the Inputs and Outputs.

The Ether1616 as the name implies communicates with the Centroid CNC12 software via Ethernet connection to the CNC PC. Ether1616 documentation is here.

Requirements for use with Acorn

- CNC12 V.4.20+

$60.00

- Emergency Stop Button (#14534) includes:

- 1x E-Stop Button

- Industrial quality reliable Emergency Stop Button with two switches.

- Two contact closures for two estop circuits

- Use just one contact closure or use both

- For use with the Acorn, AcornSix, Allin1dc, Oak, Hickory, and MPU11 CNC control boards.

- Thru Hole Panel Mount

$299.00

- WMPG-6 Kit (#9606) includes:

- 1x WMPG-6 Wireless MPG pendant

- 1x USB Wireless Transmitter / Receiver

- 1x Mounting Bracket

Take the control to where the work is! A game changing tool, the Centroid Wireless MPG handwheel CNC Control pendant allows the operator to set up jobs and tools conveniently and precisely remotely. No software or drivers to install. Plug and Play with Centroid CNC12 Pro CNC software, just plug in the included USB transmitter/receiver and start using it! Perfect for all types of Mills, Lathes, Routers and other specialty CNC machines. Control up to Six Axes from the palm of your hand! Multiple units can be used in the same location without issue.

Requirements for use with Acorn

- Acorn CNC12 v4.64+ w/ Mill Pro, Mill Ultimate, Lathe Pro, Lathe Ultimate, Router Pro, Router Ultimate, Plasma Pro, or Plasma Ultimate License

Oak, Allin1DC, Hickory, and MPU11 system Requirements

- CNC12 v4.20+ with Pro or Ultimate License

- Older systems may require a PLC update to fully support WMPG-6 features and functionality. Contact us or your System Integrator for compatibility questions, upgrade instructions, or a PLC Upgrade quote, if required due to existing custom PLC functionality.

$699.00

- KP-3 CNC Touch Probe (#14946) includes:

- 1x KP-3 Probe

- 1x 2.5 mm x 40mm Carbide Stem, Ruby Tipped Stylus

- 1x Stylus Wrench

- 1x KP-3 to Acorn Lead

- 1x KP-3 Users Manual

- 1x KP-3 to Centroid Controller Schematic

Part, Vise and Fixture Probing: Automatically Set Zero points fast and accurate.

Use the KP-3 probe to quickly and accurately find zero points on a vise, fixture or part. Eliminate operator error when setting zero points, finding edges, or center locations of bosses or bores, slots and webs. Eliminates the need for a centerfinder or an edgefinder. You'll never have to spend 30 minutes using a center finder to locate the center of a bore again. The probe will find and set the center of a bore in just seconds. In addition, the probe can be used to verify part dimensions and locations and many other applications. The KP-3 mounts in any 1/2" or 10mm tool holder and has concentric adjustment screws. Also compatible with Mach3/4, WinCNC, LinuxCNC, Pathpilot and others.

Replacement or additional probe tips can be purchased here.

Compatible with:

$660.00

- TT-4 Acorn/AcornSix Kit (#15135) includes:

- 1x TT-4 Tool touch probe

- 1x Carbide Touch surface

Mill, Lathe or Router use. Quickly and accurately setup tool heights in the tool library with a push of a button. The CENTROID TT-4 automatic tool height offset touch probe is plug and play with all Centroid CNC controls. Eliminates gauge blocks, paper, and repeated measurements. Save time and increase accuracy. Fully integrated into the CNC control tool library menu, just select the tool and press auto measure to set the tool height automatically. Makes measuring all types of tools faster and more accurate. Find the longest insert in a multiple insert tool quickly. Once you start using the TT-4 you'll wonder why you waited to purchase this time saving tool. Measure just one tool or a whole group of tools at once. Can also be used in the middle of a job to measure a replacement tool. Integrated with an Automatic tool changer for batch tool measurement. The TT-4 is based on KP-3 touch probe technology and is a robust kinematic design and works with all spindles even ones that with non-conductive bearings (ceramic) or tooling that doesn't conduct (diamond). Note: Also compatible with most all other CNC controller such as but not limited to: Mach3/4, WinCNC, LinuxCNC, Pathpilot and others.

$725.00

- Lathe TT-4 Acorn/AcornSix Kit (#15274) includes:

- 1x Lathe TT-4 Tool touch probe

- 1x Carbide Touch surface

- 1x 1/2" Mounting Shank

For Lathe use. Quickly and accurately setup tool heights in the tool library with a push of a button. The CENTROID Lathe TT-4 automatic tool height offset touch probe is plug and play with all Centroid CNC controls. Eliminates gauge blocks, paper, and repeated measurements. Save time and increase accuracy. Fully integrated into the CNC control tool library menu, just select the tool and press auto measure to set the tool height automatically. Makes measuring all types of tools faster and more accurate. Find the longest insert in a multiple insert tool quickly. Once you start using the Lathe TT-4 you'll wonder why you waited to purchase this time saving tool. Measure just one tool or a whole group of tools at once. Can also be used in the middle of a job to measure a replacement tool. Integrated with an Automatic tool changer for batch tool measurement. The Lathe TT-4 is based on KP-3 touch probe technology and is a robust kinematic design and works with all spindles even ones that with non-conductive bearings (ceramic) or tooling that doesn't conduct (diamond).

$725.00

- TT-1 CNC Tool Height Measurement Device (#10220) features:

- - Set Tool Lengths automatically

- - Ultra accurate conductive design

- - Save time, increase accuracy

- - Magnetic base or hard mounts (T-nut or Shank)

- - Works w/ CENTROID & most other CNC’s

- - Easy to achieve high precision measurements

- - Designed for milling and lathe applications: Knee mills, Bed mills, Machining centers and Routers, Lathes and Turning centers

- - In process tool reset for worn out or broken tools

- - Requires conductive tools

- - Serviceable unit

- - Auto cable detection

Set up your tools in a quarter of the time it would normally take. If you often machine short-run parts and are always setting up and tearing down for a new job, the TT-1 Auto tool set will save you time while more accurately setting your tool height offsets. Save time when you have to replace a dull tool with a new one in the middle of a job. The TT-1 is completely automatic. Press “measure” and the tool will automatically touch off the TT-1 and set the tool height offset in the tool library. Works with CENTROID CNC controls and most any other CNC or DRO with a probe input. Requires conductive tooling and spindle.

$159.00

- Centroid Offline INTERCON (#15100) Features:

- - For those that do not want to use or learn a CAD/CAM system to make CNC parts.

- - Program parts in the comfort of your office.

- - Program while the machine is running a job.

- - Easy part program transfer from your PC to the control via LAN or USB.

- - True G-code backplot graphics, see exactly what the machine toolpath will be.

- - Use on the same PC as your CAD system.

- - A USB Keylock allows user to install software on as many computers as they want.

- - Offline programming USB keylock is shipped the next business day.

- - Works with Windows 7/8/10/11*

- - Manual with tutorial examples see Mill Chapter 10, Lathe Chapter 7

- - Download offline conversational programming software here

- Scroll down to Oak and Allin1DC section.

The offline programming software runs without USB keylock but limited to 20 lines of Intercon. Plug in the USB keylock for unlimited conversational programming operation.

Installation instructions here and a video showing installation of Offline INTERCON.

Replacement Parts

$27.00

If you are purchasing a new Acorn kit, you do not need to purchase this item.

The Acorn Relay Board Kit (#14734) Includes:

1x Acorn “8 Relay Module”

1x Ribbon Cable

$17.00

Acorn Plexi Cover Kit (#15343) Includes:

1x Plexiglass Cover for Acorn

4x 6-32x3/4" Standoffs

4x 6-32x3/8" Screws

If you are purchasing a new Acorn kit, you do not need to purchase this item.

Free Shipping for Contiguous USA, Add $12 USD for International shipping. Ships via First Class Mail (USPS).

Starting on July 3rd, 2023 these plexiglass covers are included with the purchase of an Acorn CNC Control Kit. This product listing is available for those who purchased an Acorn Kit prior to July 3rd, 2023 and wish to purchase a plexiglass cover for their Acorn Control Board or for those with a damaged cover seeking a replacement.

These are plexiglass covers, do not clean with Alcohol based products or damage may occur.

Compatible with:

$39.00

If you are purchasing a new Acorn kit, you do not need to purchase this item.

This Adapter kit is for early Acorn Boards sold in 2017 and 2018.

The Legacy Acorn Relay Board Kit (#15289) Includes:

1x Acorn “8 Relay Module”

1x Ribbon Cable

1x Acorn Relay Adapter Card with 5 vdc pig tail.

More Information Available Here

Legacy Acorn_rev3 CNC Controller Specifications Manual

Factory Direct Support

Price range: $120.00 through $360.00

Professional experienced Centroid CNC control engineers will work with you to configure your CNC machine tool.

Centroid Factory Direct Technical Support is provided through Phone, E-mail, and the preferred and most effective method is remote support via TeamViewer.

Tech support time can be used for PLC updates and edits, macro writing and assistance, Centroid CNC software configuration, Centroid CNC hardware configuration, and limited third-party software and/or hardware assistance based on scale and scope of issue.

After Purchasing Technical Support Fill out this Support Request form.

Then, Please call to schedule a one-on-one CNC Tech Support appointment. +1-814-353-9256 press 4. Mon-Fri 9-5 EST

Have your TeamViewer ID and password ready. See this forum post for how to setup Teamviewer.

The CNC Engineer will ask you for detailed Photos of the machine tool and of the control cabinet as photos are worth a thousand words. The best way to provide photos is to post them to a online photo album and send the link to the album to support@centroidcnc.com (Google photos is free and the preferred method.)

Tech Support Time is non-refundable, we will keep track of tech support time used and any unused time will remain in our system for future Tech Support Calls

Centroid Acorn CNC controller reviews

Next, the forum along with YouTube videos are great. Keith, Marty, Gary and Franco not only show how to use the Acorn, but teach general principles about CNC machining. Late last night when I couldn't sleep, I watched a video where Keith showed how to use a vertical mill. The video contained everything that anyone would need to see how to use Centroid products to make their equipment work. Clicking on "Acorn User Videos" from the Acorn page shows a list of videos that show how to use the Acorn. Going on YouTube and searching "Marty CNC" brings up Marty's channel with a comprehensive list of how-to videos. Searching "Gary Campbell CNC" brings up Gary's channel and his expertly produced videos. (Gary and I go back decades to my Shopbot days when I constantly used his advice to solve my problems.) Clicking on "Centroid CNCKeith" brings up Keith's videos. His knowledge and easy-going style should make anyone comfortable in trying an Acorn. One of his videos was with "MecTechMike". Mike's mill and lathe conversions should impress everyone. He surely impressed me and gave me ideas that will take at least a year to try. There are many, many others who have taken the time to post videos showing how they use the Acorn and other Centroid products.

The forum is invaluable. Questions are answered expertly (in most cases). Since I tend to be disruptive in some of my posts (unintentionally - I like to think outside the box and try things that might seem to be controversial), I expected harsh feedback or even censoring, but I've been treated with respect and courtesy. More, importantly, by reading what others are doing, I get ideas that would take a life-time to implement.

Thanks Centroid and thanks to all of you in the Acorn community for your help.

All prices and specifications are subject to change without notice